Automation And The Commercial Kitchen

Ever since 2020, the restaurant and foodservice industry has undergone a seismic shift. While before, it was easier for restaurants to maintain worker capacity and fulfill orders, the current labor shortage is hitting these businesses where it counts. Fortunately, automation alleviates these problems, but how can technology turn the tide?

In January of 2021, only eight percent of restaurant operators said their biggest challenge was hiring and retaining new employees. By July, that number swelled to 78 percent. As lockdowns and mandates lifted, consumers were eager to get back to normal, but the industry struggled to ramp up to meet demand.

Fortunately, automation and robotics are becoming much more widespread across industries, and consumers are far more accepting of them today than in years past. While it might have seemed bizarre to have a robot mix a drink in 2018, it seems commonplace in 2022.

According to restaurant insiders, thousands of restaurants of all sizes will likely implement automation in some fashion. But automation isn't just robots. It's also having programming equipment to complete tasks like ending cook times and rotating trays so staff doesn't have to. Not only can these machines alleviate staff shortages, but they can also lead to labor savings, higher output, and better consistency.

The Bottom Line

The restaurant industry has often resisted technology adoption because labor has always been plentiful and cheap. However, now that that's not the case, operators and owners have to get creative. Fortunately, high-tech automation solutions offer various benefits, and it's easy to calculate the numbers. Overall, a robot costs a lot to purchase and install, but it's much cheaper and more efficient than a human worker once it's up and running. Also, there are fewer errors, so a restaurant can avoid refunds and delays, especially during peak order times.

Technology is also necessary, thanks to the proliferation of third-party ordering apps. Now that customers can order dishes for pickup or delivery, restaurants are getting twice as many orders in the same period, so staff has to work hard to keep up. A robot can augment these rushes and help strengthen the business' bottom line.

Automation Solutions for the Commercial Kitchen

While it's easy to understand the larger impact of robotics and automation, what do these elements look like in real life? Here are a few ways that businesses can adapt to the new normal:

Self-Service

Automated devices like the Concordia coffee machine allow customers to make their own beverages on-demand. Since the machine can customize drink orders on the fly, workers can focus on preparation, cleaning, and maintenance.

Locker cabinets can also make it easier for customers to pick up their orders without interacting with a cashier or delivery person. One perfect example is the Carter-Hoffmann Pick Up Cabinet (PUC). Able to take customers seamlessly from online ordering to paying to non-contact pickup, the PUC allows businesses to get orders out the door and monitor inventory, all without extra labor.

Faster Food Preparation

What if a single employee could prepare six dishes at once? With automated machinery, it's possible. For example, a worker could put in an order of fish and chips in a Perfect Fry fully automatic fryer. The device automatically cooks the dishes and pulls them out so they don't burn. Next, the employee could set some proteins or pizzas on a Middleby Marshall CTX conveyor oven, so they cook evenly and comes out at the perfect temperature, without monitoring.

Finally, the same person can use a TurboChef Bullet to cook an appetizer or a Blodgett commercial oven to prepare other items while waiting for the other machines. With all of these tools, one person can prepare and deliver multiple items at the same time it would take someone else to make one dish by hand.

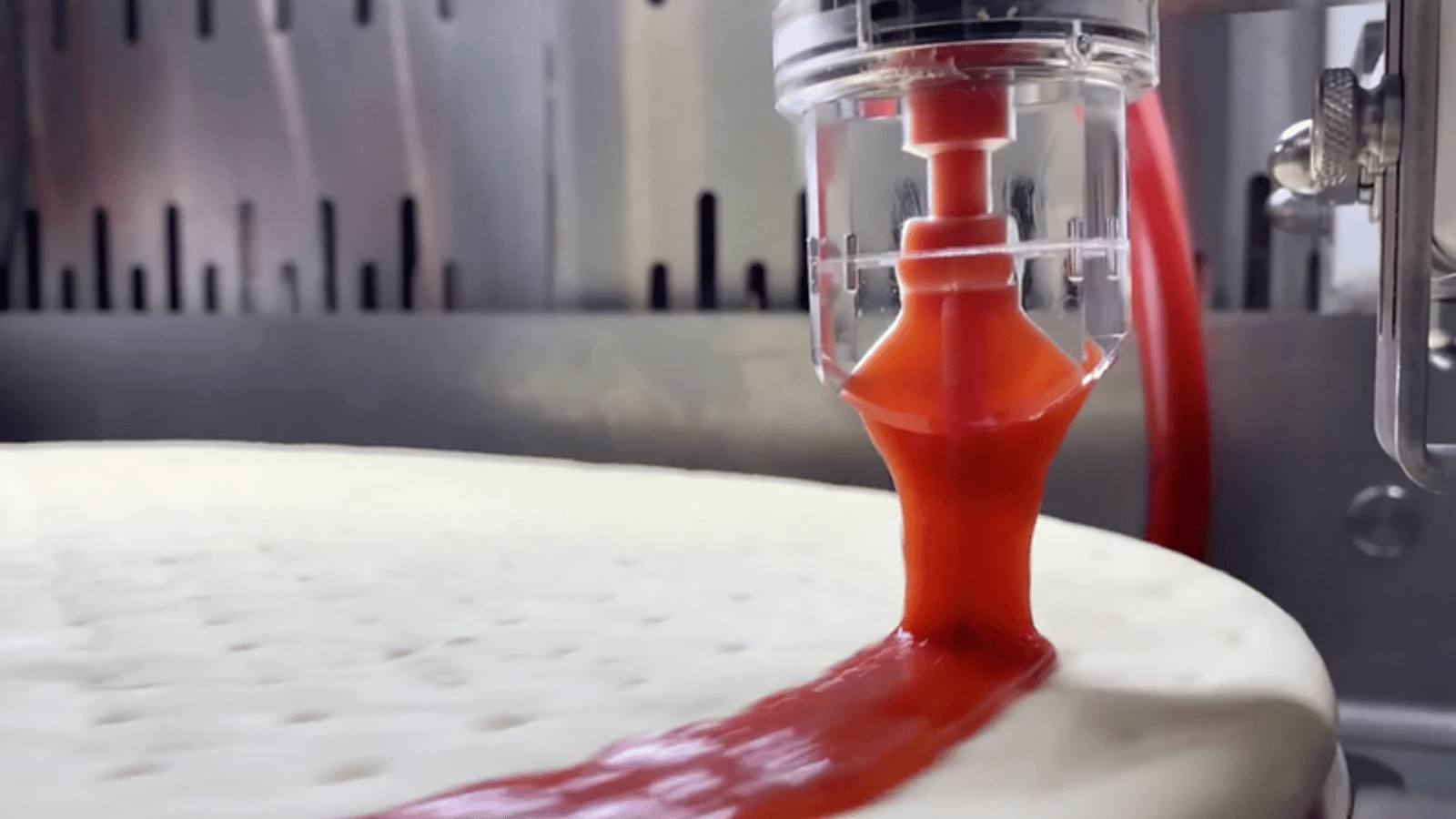

Individual Dish Creation

Foodservice businesses that create menu items that are repetitive, like pizzas, use automation like PizzaBot to automatically distribute sauces and toppings. Since the machine only creates one dish, it's easy to replicate dozens or hundreds of times throughout the day. All workers have to do is refill the ingredients and monitor the device for any errors or glitches. It's also perfect for businesses that are packaging pizzas for re-sale.

Subscribe Here!

Topics

- Anets (1)

- Atlas Metal (2)

- Automation (4)

- Bar/Brewery (6)

- Beverage (11)

- Blodgett (5)

- Bluezone (5)

- C-Stores (4)

- Carter-Hoffmann (4)

- Champion (1)

- Colleges & Universities (4)

- Concordia (6)

- cooktek (2)

- Deutsche (1)

- DeVere (6)

- Dishwashing (1)

- Evo (3)

- Firex (2)

- Follett (5)

- Furniture (1)

- Globe (2)

- Grosfillex (2)

- Healthcare (1)

- Heartland Reps (7)

- Hospitality (3)

- Ice (2)

- Icetro America (3)

- Imperial (1)

- induction (1)

- IoT (1)

- K12 Foodservice (17)

- Kloppenberg (1)

- Lakeside (3)

- Lincat (1)

- LTI (1)

- MagiKitch’n (1)

- Marco (3)

- MEIKO (1)

- middleby marshall (7)

- Mixers (1)

- Multiteria (1)

- Perfect Fry (1)

- Pitco (3)

- Pizza (5)

- Recipes (1)

- Restaurant (23)

- Serving Lines (2)

- Southbend (3)

- Star (1)

- Synesso (1)

- Thermo-Kool (3)

- Trends (1)

- TurboChef (6)

- U-Line Refrigeration (1)

- Varimixer (1)

- Ventless (3)

- Viking (1)

- warming (1)

- Wells (2)

- Wunder-Bar (1)